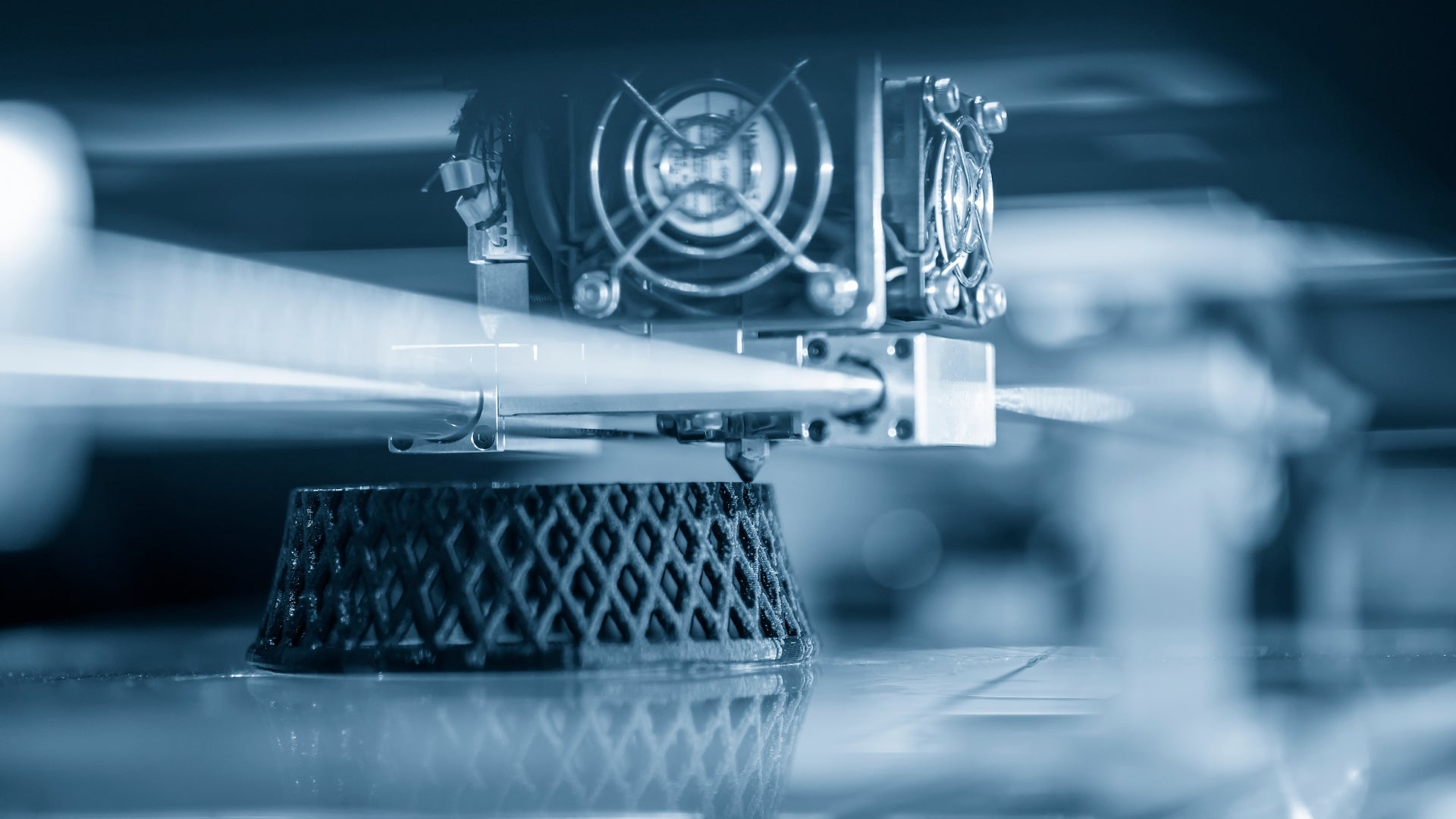

Lightweighting

Our clients requested a new design iteration that would reduce the weight of a part. Our team was able to create this (and 3 more iterations) in just a day and was able to shave off 80% of the weight! The final part did not compromise on structural requirements as this part was load bearing and needed to withstand hundreds of pounds and thousands of cycles.

Part Reduction

A common use case of Additive Manufacturing is the ability to drastically reduce the number of parts and components required in a final product. The image on the left showcases how Aersport Modeling & Design was able to take a 26 part design and reduce it to only 4! This meant less assembly, lower cost while maintaining the part functionality.

Volume Production

After prototyping with our technology, companies have chosen to switch over to production level applications due to the durability of parts provided.